Material Specifications

Screen

- Mesh: 18×14

- Diameter: .011″

- Finishes: Charcoal color only

- Made is U.S.A.

- Resilient, long lasting

- Easy to install

- Will not crease, dent, or unravel

- Withstands all climates, salt air, and industrial fumes

Our company’s fiberglass insect screening is woven from high quality fiberglass yarn that is precisely coated with a protective material. All fiberglass products are manufactured under strict standards to assure that the colors are consistent and the mesh is uniform.

Technical Characteristics

Physical Properties

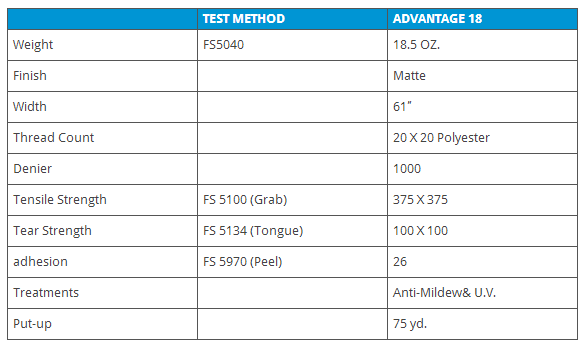

- Extremely Strong And Durable

- High Tensile Strength

- Anti-Mildew Treatments & U.V. Pigments For Weather ability

Zippers

To assure the creation of zippers that can out-perform and out-last the competition, overhead door screens has it’s design engineers contract manufactures that have their own zipper producing machinery

Materials

Materials Used for Making Overhead Door Screens.

To assure the creation of zippers that can out-perform and out-last the competition, Overhead Door Screens have design engineers contract manufactures that have their own zipper producing machinery.

Quick & Easy Answer to the Most Commonly Asked Question

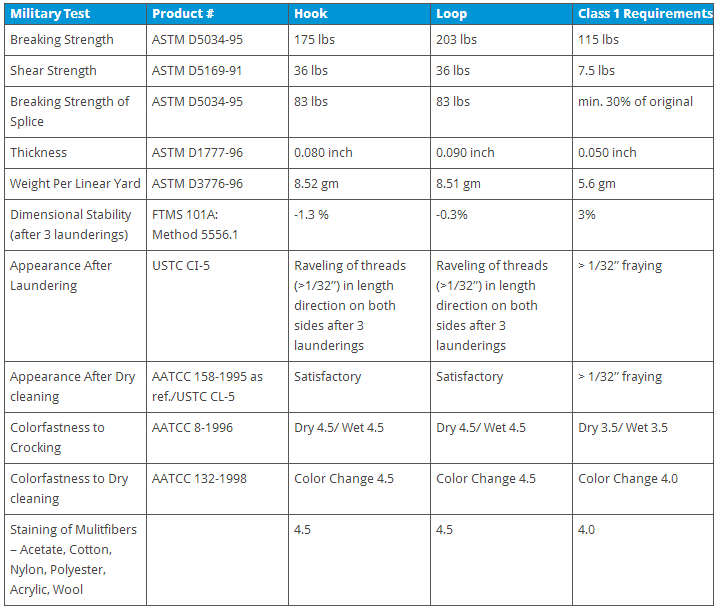

What’s the difference between the Hook & Loop tape?

1″ Regular Poly-Pro Webbing On Top and Sides of Screen

Rated tensile strength 600 Lbs.

18.5 OZ. Vinyl Coated Polyester

Appearance

Environmental Conditions

Pressure Sensitive Hook and Loop

Quality and delivery are assured as our company offers our own in-house, state-of-the-art hot melt coating facility. Adhesives and coating are continuously being developed for use in the packaging, display, automotive, aerospace, and other industries industry. As a result, we offer the highest quality hook and loop available.

- High tack–quick-setting.

- Achieves 90% bond strength in approximately one hour. Full strength: 24 hours.

- Temperature operating range: 40F – 190 F.